TECHNOLOGY: OUR TEAM IS OUR BEST GUARANTEE

| All our machinery is suited to all the current market requirements in order to satisfy our clients' needs in quality and service at the best price to enable us to ensure the highest quality in manufacturing processes and methods. Our working capacity is between 50.000 and 55.000 hours annually. Talleres Cidal´s staff is highly qualified and trained to offer optimum levels of guarantee of the product and service. Our plant is air-conditioned between 19º-21º in order to assure accuracy to all the single parts that we machined providing a stable environment in all stages of manufacturing and verification. | |

|

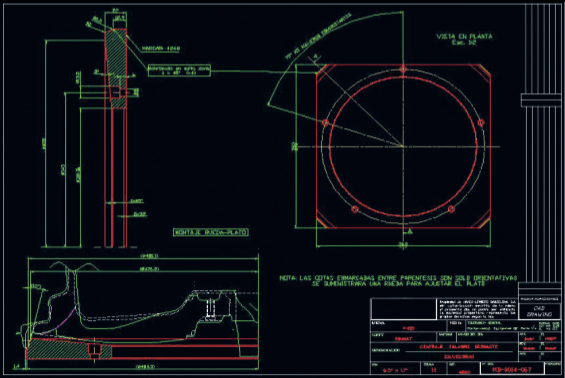

We have an exclusive computerized intelligent control system which allows us to perfectly manage planification, production control, follow-up and management of the quality from the arrival of the order up to the completion of the service. We are equipped with the latest computer system for CAD-CAM. That is combined with our experience with machining and our working ability, which allows us to provide the client with optimal conditions of machining and post delivery. The speed and quality of our response enables our clients to save time and unnecessary costs. |

We have a rising desire to innovate, since this means facing new ways and new challenges and, of course, we direct all our efforts, making investments in technology, to compete with advantage in the national and international market.

NUMERICAL CONTROL LATHE TCN-11 LEALDE

DIMENSIONS:

- Front bearing inner diameter (mm): 110 – 130 - 160.

- Viahole diameter main shaft (mm): 75 – 91 - 115

- Swing over longitudinal guides (mm): 520

- Swing over cross guides (mm): 350

- Maximum distance between nose and counterpoint: 575 - 975

- Type of main spindle nose: 6” – 8” – 11”

- Chip collector.

- Maximum speed of the main shaft (r.p.m.): 4000

NUMERICAL CONTROL LATHE DANOBAT TCN-10

DIMENSIONS:

- Height between points and ground: 920 mm.

- Maximum allowable diameter over bed: 450 mm.

- Maximum allowable diameter over carriage: 210 mm.

- Maximum diameter air turnable: 280 mm.

- Turnable diameter on the carriage: 210 mm.

- Maximum distance between the nose of the main spindle and the tool holder disc face: 550 mm.

- Maximum distance between nose and counterpoint: 520 mm.

- Swing over longitudinal guides (mm): 500 mm

- Swing over cross guides (mm): 171 mm

KIT INCLUDED:

- Three hollow hydarulic clutches plat (Ø210 mm)

- Chip collector.

- Bar feeder HIDROBAR.

- Parts picker.

NUMERCAL CONTROL LATHE GOODWAY GS-200/L

DIMENSIONS:

- Height between points and ground: 1055 mm.

- Maximum allowable diameter over bed: 670 mm.

- Maximum allowable diameter over carriage: 210 mm.

- Maximum diameter air turnable: 280 mm.

- Turnable diameter on the carriage: 400 mm.

- Maximum distance between the nose of the main spindle and the tool holder disc face: 772,7 mm.

- Maximum distance between nose and counterpoint: 520 mm.

- Swing over longitudinal guides (mm): 600 mm

- Swing over cross guides (mm): 142,7 mm

KIT INCLUDED:

- Three hollow hydarulic clutches plat (Ø210 mm)

- Chip collector.

- Bar feeder BARLOAD model BA-65:

- Bar diameter: From 5 to 6

- Bar length: 1500 mm.

- Parts picker.

CYLINDRICAL LATHE HARRISON V460

DIMENSIONS:

- Maximum allowable diameter over bed: 500 mm

CYLINDICAL LATHE HARRISON V390

DIMENSIONS:

- Maximum allowable diameter over bed: 400 mm.

NUMERICAL CONTROL SAW CR-260 A CN

FEATURES:

- Cutting capacity 260 mm round.

- Cutting Capacity Rectangle 270x260 mm.

- Maximum with 260x150 mm vertical jaws.

- Dimensions 4090x25x0.9 mm tape.

- Table height 760 mm.

- Diameter 400 mm of handwheels.

- Tape speed 18-108 m. / Min.

MILLING MACHINE MRF FU-160

DIMENSIONS:

- Length automatic with steering wheel 1240 mm

- Transverse automatic 300 mm.

- Automatic Vertical 550 mm.

- Min. - Max. mandrel 0-425

MILLING MACHINE LAGUN FTV-4.SP (2 MACHINES)

DIMENSIONS:

- Longitudinal 800 mm.

- Transverse automatic 425 mm.

- Vertical 400 mm.

MILLING MACHINE LAGUN FU-125

DIMENSIONS:

- Longitudinal automatic with steering Wheel 825 mm.

- Transverse automatic 425 mm

- Min. - Max. mandrel 0-425 mm

NUMERCIAL CONTROL MILLING MACHINE ANAYAK-MATIC-7 CNC

FEATURES:

- Warehouse 20 tools.

- Fanuc Control OMC with:

- Electronic handwheel.

- Quick screw.

- Preparation 4th axis.

- Fanuc spindle motor 12 p. 5.5/705 and 35-6000 R.P.M.

- No change of range.

- Cone BT-40.

- Voltage: 380 V-50 Hz

DIMENSIONS:

- 800 mm X axis travel. (31.5 ")

- 450 mm Y-axis travel. (17.7 ")

- 505 mm Z axis travel.

- Spindle nose to table surface 105-630 mm.

- Spindle Center to column surface 480 mm.

- Surface soil 850 mm table.

- Center column table surface 255-705 mm.

- Table dimensions 425-950 mm.

- Maximum weight allowed 500 kg

- Slots T 18 mm * 3 * 100 mm.

- Spindle speed 60-6000 R.P.M.

- Tool change time 3.5 sec.

NUMERICAL CONTROL MILLING MACHINE ANAK-MATIC-10 CNC

FEATURES:

- Warehouse 30 tools.

- Fanuc Control OMC (4-axis) with:

- Electronic handwheel.

- Fast threaded.

- Preparation 4th axis.

- Fanuc spindle motor 12 p. 7.5 / 9 and 60-6000 R.P.M.

- Cone BT-40 + strut MAS-BT-40-I.

DIMENSIONS:

- 1000 mm X axis travel.

- 500 mm Y-axis travel.

- 505 mm Z axis travel.

- Table:

- 1150 x 475 mm.

- Rectified central slot 18 H7

- Number of T-slots: 4

- Separation: 100 mm.

- Fast Forward: X-Y 24 000 mm. / Min.

- Fast Forward: Z 15.000 mm. / Min.

- Time change tools: 3.5 sec.

- Time chip to chip tool change: 9 sec.

- Cooling system external tool 66 l. / Min.

NUMERICAL CONTROL MILLING MACHINE AWEA BM-1020

FEATURES:

- Warehouse 32 tools.

- Fanuc Control WTO (4-axis) with:

- Electronic handwheel.

- Fast threaded.

- 4th axis.

- Fanuc spindle motor 12 p. 7.5 / 9 and 60-6000 R.P.M.

- Cone BT-40 + strut MAS-BT-40-I.

DIMENSIONS:

- 1000 mm X axis travel.

- 500 mm Y-axis travel.

- 505 mm Z axis travel.

- Table:

- 1150 x 475 mm.

- Rectified central slot 18 H7

- Number of T-slots: 4

- Separation: 100 mm.

- Fast Forward: X-Y 24.000 mm. / Min.

- Fast Forward: Z 15.000 mm. / Min.

- Time change tools: 3.5 sec.

- Time chip to chip tool change: 9 sec.

- Cooling system external tool 66 l. / Min.

NUMERICAL CONTROL MILLING MACHINE OF HIGH PRECISION AND SPEED MAKINO PS95

WORK AREA:

- X-axis races (side head) 920 mm

- Car Strokes Y-axis (longitudinal table) 510 mm

- Strokes Z axis (vertical head) 460 mm

- Distance from the surface of the table to the nose of the spindle 150-600 mm.

T-SLOT TABLE:

- Dimensions 1.170 x 510 mm

- T-slot 18 H7

- T-slot number 5

- T-slot width 100 mm

- Maximum table load 800 kg

HEAD UNIT:

- Power 25 / 18,5 kW

- Turning speed 120 - 14,000 min -1

- Diameter of inner bearing 85 mm / 130 mm.

- Cone of attack HSK 63A

- Pair of copy 175/117/96 Nm.

ADVANCES:

- Cutting speed 1 - 30,000 mm / min

- Fast moving 36/36/30 mts / min

AUTOMATIC TOOL CHANGER:

- Storage capacity of tools 30 tools

- Chip / chip change time 3.6 sec

- Time change tool / tool 1.2 sec

- Max. tools 8 kg

- Max. tools Ø 125 mm, L = 300mm

PRECISIONS:

- Positioning: (throughout the course) / with rules + -0,0025 / + - 0.0015 mm.

- Repeatability: idem + -0,002 / + - 0.001 mm. Storage of 30 tools with shift arm.

CONTROL FANUC PROFESSIONAL SYSTEM P (TOUCH SCREEN):

- 400 concurrent programs and sub-programs

- Polar coordinates

- 48 additional 1parts of working coordinates

- Coordinate rotation (g68 / 69)

- Hard threaded

- Mirror function

- Re-start program.

- Increased memory up to 512 kb

- Helical interpolation

- High skip speed function

- Automatic corner control.

NUMERICAL CONTROL MILLING MACHINE OF HIGH PRECISION AND SPEED MAKINO PS-105

CHARACTERISTICS:

- Work area:

- X-axis races (side head) 1050 mm

- Car Strokes Y-axis (longitudinal table) 510 mm

- Strokes Z axis (vertical head) 460 mm

- Distance from the surface of the table to the nose of the spindle 150-600 mm.

- T-slot table:

- Dimensions 1.300 x 510 mm

- T-slot 18 H7

- T T-slot number 5

- T-slot width 100 mm

- Maximum table load 800 kg

- Head Unit:

- Power 30/ 18,5 kW

- Turning speed 120 - 14,000 min -1

- Diameter of inner bearing 85 mm / 130 mm.

- Cone of attack HSK 63A

- Pair of copy 175/117/96 Nm.

- Advances:

- Cutting speed 1 - 30,000 mm / min

- Fast moving 36/36/30 mts / min

- Automatic tool changer:

- Storage capacity of tools 30 tools

- Chip / chip change time 3.6 sec

- Time change tool / tool 1.2 sec

- Max. tools 8 kg

- Max. tools Ø 125 mm, L = 300mm

- Precisions:

- Positioning :( throughout the course) / with rules + -0,0025 / + - 0.0015 mm.

- Repeatability: idem + -0,0025 / + - 0.001 mm. Storage of 30 tools with shift arm.

- Control Fanuc Professional System P (touch screen) with:

- 400 concurrent programs and sub-programs

- Polar coordinates

- 48 additional 1parts of working coordinates

- Coordinate rotation (g68 / 69)

- Hard threaded

- Mirror function

- Re-start program.

- Increased memory up to 512 kb

- Helical interpolation

- High skip speed function

- Automatic corner control

- Marpos’ System

NUMERICAL CONTROL MILLING MACHINE OF HIGH PRECISION AND SPEED LAGUN L-1400

CHARACTERISTICS:

- Work area:

- X-axis races (side head) 1430 mm

- Car Strokes Y-axis (longitudinal table) 670 mm

- Strokes Z axis (vertical head) 640 mm

- Distance from the surface of the table to the nose of the spindle 150-610 mm.

- T-slot table:

- Dimensions 1.500 x 620 mm

- T-slot 18 H8

- T T-slot number 5

- T-slot width 125 mm

- Maximum table load 1200 kg

- Head Unit:

- Power 15/ 22,00 kW

- Turning speed 120 - 14,000 min -1

- Diameter of inner bearing 85 mm / 130 mm.

- Cone of attack HSK 63A

- Pair of copy 175/117/96 Nm.

- Advances:

- Cutting speed 1 - 30,000 mm / min

- Fast moving 36/36/30 mts / min

- Automatic tool changer:

- Storage capacity of tools 30 tools

- Chip / chip change time 3.6 sec

- Time change tool / tool 1.2 sec

- Max. tools 8 kg

- Max. tools Ø 125 mm, L = 300mm

- Precisions:

- Positioning :( throughout the course) / with rules + -0,0025 / + - 0.0015 mm.

- Repeatability: idem + -0,0005 / + - 0.001 mm. Storage of 30 tools with shift arm.

- Control Fanuc Professional System P (touch screen) with:

- 400 concurrent programs and sub-programs

- Polar coordinates

- 48 additional 1parts of working coordinates

- Coordinate rotation (g68 / 69)

- Hard threaded

- Mirror function

- Re-start program.

- Increased memory up to 512 kb

- Helical interpolation

- High skip speed function

- Automatic corner control

- Renishaw System

QUALITY

- Metronic profile projector.

- Inside measuring instruments:

- Micrometers

- Digital calipers

- Depth measuring instruments

- QM height

- Linear height

- Dial indicator

- Joinet magnetic stand

- Hardness testing machine.

- Surface roughness machine

- Granite surface plate

- Gauge blocks

IMPORTANT NOTE:

- Each of our milling machine are included displays.

- We have CAD-CAM programmer connected to all our CNC machines (CNC - CDM)